In the dynamic and ever-evolving landscape of procurement and supply chain management, establishing and nurturing strong supplier relationships is a cornerstone of success. Strong supplier partnerships are lifesaving food for every organization to gain their business and sustainability. In this article, we will delve into five significant strategies that aim to boost supplier relationships which are indispensable. These strategies molded through years of experience and adaptation, are the keys to unfolding the full potential of eProcurement for lasting. Whether you are a procurement officer in steel plant or navigating the complex world of pharma procurement or managing your IT procurement, the insights discussed here are universally applicable and vital for enhancing your supplier relations.

The Importance Of Strong Supplier Relationships:

Building and maintaining strong relationships with suppliers not only ensures a steady supply of goods and services; it is a strategic move that can have a significant influence on your business’s overall growth and sustainability. Poor supply relationships lead to the following issue.

The following are two significant case studies about supply chain issues and their impact on business.

Procurement Strategies For Strong Supplier Relationships:

Establishing robust supplier relationships is strategically imperative. Implementing eProcurement within an organization not only enhances business prospects but also plays a crucial role in fostering a sustainable and resilient supply chain. Following Five essentials’ strategies to help you improve your supplier relationships and, in turn, boost your business’s sustainability:

1. Open and Honest Communication:

In today’s digital age, effective communication stands as the backbone of successful supplier relationships in procurement. Leveraging eProcurement platforms, businesses can ensure seamless interaction between buyers and suppliers, providing real-time updates on orders, deliveries, and inventory levels. This transparency not only minimizes errors but also fosters trust and clarity in the collaboration process. Through features like digital channels and supplier portals, eProcurement systems offer a robust framework for open and honest communication, thereby driving efficiency and innovation in supplier relations.

McKinsey’s research underscores the importance of closer relationships between buyers and suppliers in enhancing supply chain resilience. They found that supply chains are vulnerable to disruption, leading to significant profit losses for companies. Digital platforms play a crucial role in facilitating this collaboration by providing seamless communication and interaction, essential for building strong and resilient supply chains.

For example, companies like Toyota and Nike have successfully utilized digital platforms during times of disruption. Toyota’s revamped production strategy and regionalized supply chains allowed them to resume production just two weeks after a major earthquake in 2016. Similarly, Nike used RFID technology to track products during the early stages of the pandemic, ensuring efficient management of their supply chains.

These examples illustrate how digital platforms can facilitate open and honest communication, providing real-time updates and establishing clear lines of communication. This not only enhances supply chain resilience but also strengthens supplier relationships.

In conclusion, integrating digital platforms into eProcurement strategies, as highlighted by McKinsey’s research, is crucial for fostering closer relationships between buyers and suppliers, thereby enhancing supply chain resilience. This is achieved through transparency, interaction, and open and honest communication.

2. Enhancing Transparency & Visibility:

In the realm of eProcurement, transparency and visibility are paramount. These features offer a crystal-clear view of the process, granting real-time access to crucial information such as qualification details, price comparisons, order and inventory statuses. With eProcurement platforms, both buyers and suppliers can easily access this information from their respective dashboards, fostering a shared understanding and eliminating room for hidden agendas or misunderstandings. Real-time tracking and reporting capabilities further enhance this transparency, allowing parties to monitor order progress, delivery schedules, and payment statuses. This data-driven approach ensures informed decision-making, smoother operations, and provides an audit trail for resolving disputes effectively.

The International Fund for Agricultural Development (IFAD) adopted a revolutionary digital procurement solution to enhance transparency, competition, and value in procurement processes. Before its implementation, IFAD and its borrowers grappled with disjointed systems for project procurement reporting, leading to inefficiencies and complexities. Bid documents, evaluation reports, and procurement plans were managed through separate platforms, hindering smooth operations and effective monitoring. Recognizing the need for reform, IFAD embarked on exploring innovative solutions to streamline the process. This case study underscores the transformative power of eProcurement strategies in fostering transparency and visibility. By leveraging real-time tracking and reporting capabilities, organizations can enhance supplier relationships, enable informed decision-making, and efficiently resolve disputes, ultimately driving smoother operations and maximizing value.

3. Enhancing Supplier Collaboration Through Efficient Order Processing & Payment:

Automating procurement processes and ensuring prompt payments demonstrate commitment and reliability. Prompt and accurate payments demonstrate commitment and reliability as a business partner. eProcurement systems automate and standardize the procurement process. They reduce the likelihood of manual errors, such as incorrect order numbers, order quantities, or payment discrepancies. Automated order processing and payment system help ensure that orders are accurate, and payment is made promptly, minimizing the potentials errors. Since every data is very visible to each stakeholder and as per the latest status buyer and supplier can take next action promptly. For suppliers, this means that they receive orders promptly and can plan their production, accordingly, leading to a more harmonious and efficient collaboration.

In the digital world, Procure-to-Pay (P2P) processes become automated, making transactions like processing purchase orders, requisitioning goods and services, validating reception of materials, and paying invoices more efficient and less prone to errors. According to the PwC Digital Procurement Survey 2022, the digitalization of Source-to-Pay (S2P) has become increasingly common in procurement departments. Most respondents, 90%, use either Source-to-Contract (S2C) or Procure-to-Pay (P2P) solutions. Furthermore, a significant portion, 77%, use both solutions. This trend highlights the growing reliance on digital tools to streamline and enhance procurement processes.

4. Data-Driven Performance Measurement:

Through Digital procurement evaluate Supplier performance based on data is crucial for fostering a competitive edge. eProcurement systems capture and analyze a wealth of data, making it easier to assess supplier performance objectively. Key performance indicators (KPIs) are tracked and measured in real-life. This data allows buyers to provide specific, data backed feedback to suppliers, helping them understand precisely where they can enhance their performance. eProcurement facilitates ongoing performance assessment. By sharing performance data with suppliers, eProcurement allows for constructive, data-driven discussion about areas that need improvement. Suppliers can access detailed performance metrics and work collaboratively with buyers to enhance their processes and better meet buyer expectations.

Mckinsey has mentioned in their article about a digital procurement program where procurement team will introduce the “Supplier x-ray” is a solution that collects crucial supplier data such as cost, lead times, capacities, inventories, and risks across the entire value chain. This data is gathered from various sources including proprietary systems of value chain partners, structured third-party data, and unstructured web feeds. The data is then combined into real-time profiles of a company’s tier-n supply chains. Existing elements of this approach include web-screening solutions for supplier risk management and online supplier networks. In the future, these solutions are expected to converge, providing companies with comprehensive visibility of their multi-tier suppliers.

5. Cost Efficiency and process optimization:

Reducing administrative overhead through eProcurement can lead to cost savings. When business saves money, you can pass those benefits on to your suppliers, to optimize the process to make relationships more mutually beneficial. eProcurement streamlines the procurement process, reducing administrative overhead manual tasks. This enhancement of efficiency results in cost savings for the buying organization. By lowering their operational costs, businesses can allocate resources to activities that drive innovation and growth. Additionally, they have the flexibility to pass on cost savings to their suppliers, creating a win-win situation that strengthens the relationship.

According to the PwC Digital Procurement Survey 2022, cost reduction is indeed a high priority and a key driver for digital transformation.69% of companies named cost reduction as one of their top three strategic priorities.

Conclusion:

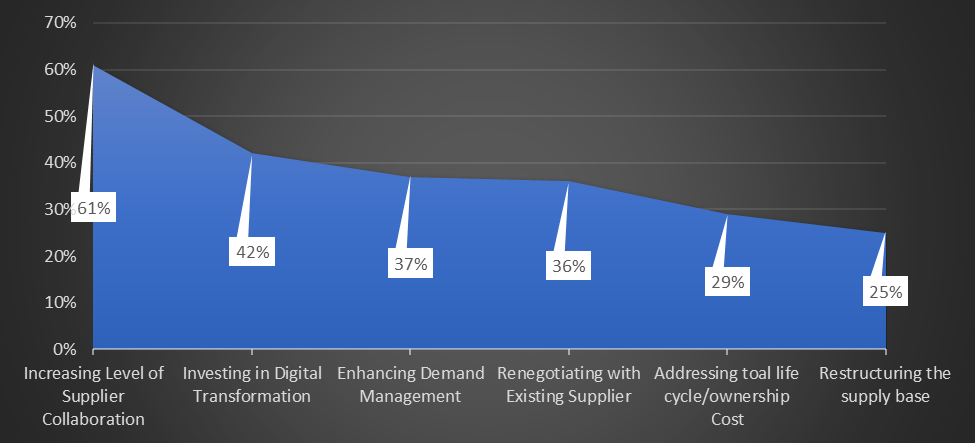

As per Delloitte 2023 Global Chief Procurement officer (CPO) survey it’s clear that supplier performance improvement is a significant focus in high-performing procurement organizations.

Top strategies to deliver the most value in 2023

A recent qualitative case study, available on DiVA, emphasizes the significant cost-saving and efficiency potential of e-procurement in the procurement process. The study also underscores the capacity of e-procurement to expand the customer base, widen the search for cost-effective raw materials, and enhance the overall advantages of e-procurement within organizations. Businesses that have adopted e-procurement have reported noteworthy savings of up to 42% in purchasing transaction costs, primarily due to reduced paperwork. This streamlined approach results in fewer errors and a more efficient purchasing process.

In the digital age, eProcurement emerges as a strategic asset for organizations aiming to enhance supplier relations. These strategies not only streamline procurement processes but also foster stronger, more collaborative partnerships. As evidenced by real-world case studies, eProcurement is a transformative tool that goes beyond transactional efficiency—it’s a catalyst for building lasting and mutually beneficial supplier relationships.

Let us know your views at contactus@mjunction.in

Reference: